There’s more to preparing your HVAC for Texas winters than flipping a switch; you should replace or clean air filters regularly to maintain airflow and indoor air quality, test your heating before cold fronts, confirm your thermostat’s accuracy, clear debris from the outdoor unit and watch for coastal salt corrosion, and inspect ducts for leaks or poor insulation. You can handle basic upkeep like filter changes, but hire a licensed technician for deeper inspections, cleaning, and performance testing to avoid costly breakdowns.

Understanding Types of HVAC Systems

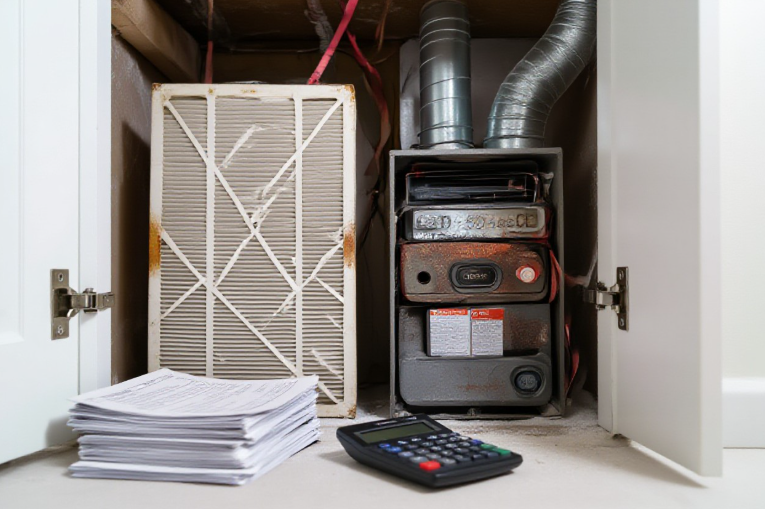

You’ll encounter several common configurations in Texas homes-forced-air central systems (gas furnaces or air handlers with heat pumps), standalone heat pumps, ductless mini-splits, and occasional boiler setups-each with different winter maintenance priorities. Gas furnaces typically carry AFUE ratings from about 80% to 98% and last roughly 15-20 years, while heat pumps perform efficiently in mild winters and often have HSPF ratings between 8 and 12; knowing these numbers helps you prioritize inspections and replacement timing.

When you prepare for cold fronts, target system-specific tasks: central systems need duct checks and blower inspections, heat pumps need refrigerant and defrost-cycle reviews, and ductless units require regular indoor-filter cleaning and outdoor-condenser upkeep to prevent coastal corrosion. Filters should be changed every 1-3 months depending on use and indoor air quality, and expect professional checks at least annually to catch issues like 10-30% duct leakage or low refrigerant that reduce efficiency and increase runtime.

- Change or clean filters every 1-3 months to maintain airflow and indoor air quality.

- Inspect ducts for leaks and insulation gaps; sealing can recover 10-30% of lost heat.

- Clear two feet of debris around outdoor units and watch for salt-related corrosion if you’re near the coast.

- Have a licensed technician perform an annual tune-up including combustion analysis for furnaces or refrigerant/checks for heat pumps.

- After you identify your system type, prioritize the checklist items above to avoid mid-winter failures.

| Gas Furnace (Central) | AFUE 80-98%; lifespan ~15-20 years; maintenance: burner/heat exchanger inspection, annual combustion check, filter changes 1-3 months. |

| Heat Pump (Air-Source) | HSPF ~8-12; effective down to ~25°F for many models; maintenance: refrigerant level, defrost cycle, coil cleaning annually. |

| Central AC with Air Handler | Shared ductwork; maintenance: duct sealing, blower motor service, condensate drain cleaning, thermostat calibration. |

| Ductless Mini-Split | Capacity 9,000-36,000 BTU per head; SEER up to ~30; maintenance: indoor filter cleaning monthly, outdoor coil check, refrigerant and electrical inspection every 1-2 years. |

| Boiler / Hydronic | Lifespans 15-30 years; maintenance: pressure checks, flushing, expansion tank inspection, annual service for leaks and controls. |

Central Heating Systems

Your central forced-air system relies on both the furnace/air handler and the distribution network, so you need to split maintenance between the equipment and the ducts. Start by scheduling an annual professional inspection that includes combustion efficiency testing for gas furnaces, blower motor amperage checks, and verifying the heat exchanger for cracks-these checks reduce the risk of unsafe operation and maintain AFUE performance in the 80-98% range.

For the distribution side, inspect and seal ducts where they run through unconditioned space; duct leakage of 10-30% is common and directly raises your winter energy bills. Replace filters every 1-3 months, keep two feet of clearance around the outdoor unit, and confirm thermostat accuracy with a calibrated thermometer so you avoid unnecessary runtime and wear on the system.

Ductless Mini-Split Systems

Ductless mini-splits give you zone-level control and typically run with indoor heads sized between 9,000 and 36,000 BTU, offering high SEER ratings that can exceed 20 in modern units. Clean the indoor filters monthly to maintain airflow and efficiency, inspect drain lines for blockage, and check for frost on the outdoor coil during cold snaps-if you see persistent icing, a refrigerant or defrost-cycle issue may be present and should be addressed by a technician.

Installation details matter: many systems allow multiple indoor heads on one outdoor compressor, but line-set length limits (often 50-100 ft depending on model) and proper refrigerant charge are critical to performance. Verify that installers pull vacuum and charge to manufacturer specs; undercharge or overcharge reduces heating capacity and increases energy use, especially during Texas cold fronts.

You should schedule a professional service every 1-2 years to verify refrigerant charge, inspect electrical connections, and treat external fins for corrosion if you’re in a coastal zone like La Marque, where salt air accelerates wear and can shorten component life.

After you identify your specific system and its maintenance priorities, adjust your winter checklist to match those tasks and schedule professional service as needed.

Essential HVAC Maintenance Tips

Change or clean your air filter every 30-90 days depending on use, pets, and indoor air quality needs; a clogged filter can reduce airflow and make your system work 5-15% harder. Test your heating system at least once before the first cold front-run it for 15-20 minutes, listen for unusual sounds, and check that each room reaches the expected temperature within 10-15 minutes. Outside, maintain a 2‑foot clear radius around the outdoor unit, rinse condenser coils gently with a hose once a year, and inspect for corrosion if you live near the coast; salt air can accelerate rust and reduce efficiency within a single winter season. Sealing obvious duct leaks (even just 5-10% of a system’s leakage) often yields measurable savings of 5-10% on heating bills and improves comfort in rooms that routinely run cold.

- Replace HEPA or pleated filters every 30-90 days; check weekly if you have pets or allergies.

- Schedule a professional pre‑winter tune‑up annually (typical cost $90-$200) to inspect heat exchangers, gas pressure, and safety controls.

- Keep 2 ft clearance around the outdoor unit and clear leaves, grass clippings, and ice buildup.

- Inspect insulation on ducts in attics and crawlspaces; add at least R‑6 where it’s missing.

- Note any sharp rises in utility bills, short cycling, or persistent odors-these are triggers for professional diagnostics.

You can handle basic upkeep like swapping filters and clearing debris, but services such as refrigerant checks, combustion analysis, and electrical tightening are best left to licensed technicians. Recognizing signs like steady increases in energy use, uneven room temperatures, or strange noises lets you act before a minor issue becomes an expensive repair.

Daily Maintenance Practices

Scan your thermostat and programming each day to ensure it’s set correctly-misprogramming can raise energy use by 5-10% over a month. Keep vents and return grilles unobstructed by furniture or curtains so airflow remains balanced; you should see no more than a 5-10°F difference between return and supply registers in normal operation. If your system has a filter indicator, check it; otherwise visually inspect pleated filters weekly during heavy use periods and replace immediately if visibly loaded.

Perform a quick visual check of the outdoor unit daily when weather is severe: remove any twigs, paper, or trash and note standing water or ice. Listen for abnormal sounds like grinding, hissing, or loud rattles during startup; those noises often precede motor or bearing failures and can help you decide whether to schedule a technician within 24-72 hours.

Seasonal Maintenance Recommendations

Book a professional tune‑up in the fall before temperatures drop: technicians should clean burners or heat exchangers, test ignition and safety controls, measure airflow and static pressure, verify refrigerant charge, lubricate moving parts, and tighten electrical connections. For heat pumps, verify defrost cycles and reversing valve operation; for gas furnaces, request a combustion efficiency test and carbon monoxide check. These inspections commonly prevent emergency calls and can maintain system efficiency within 90-100% of factory performance.

Do seasonal DIY tasks as well: replace filters, vacuum supply registers, and gently hose off condenser coils if accessible (power off the unit first). Inspect ductwork in unconditioned spaces for disconnected joints and add mastic or foil tape to small gaps; insulating exposed ducts with at least R‑6 material reduces winter heat loss and helps rooms warm faster.

When you prepare your system for winter, shut off exterior condenser units only if a technician recommends it for your heat pump, never blanket the unit, and always switch power off before any hands‑on work; for electrical, refrigerant, or combustion concerns schedule a licensed service call rather than attempting repairs yourself.

Step-by-Step HVAC Winter Maintenance Guide

Quick checklist

| Step | Action & specifics |

| Replace or clean filter | Swap disposable filters every 30-90 days (monthly if pets/allergies). For washable filters, vacuum and wash, then dry fully before reinstalling to maintain airflow and indoor air quality. |

| Pre-season system test | Run heat 1-2 weeks before cold snaps. Raise thermostat 5°F above current room temp and confirm the furnace or heat pump cycles on within 2-5 minutes and produces warm air at the registers. |

| Thermostat check | Verify accuracy with a room thermometer. Replace batteries annually and recalibrate or upgrade to a programmable/Smart thermostat if readings differ by more than 2°F. |

| Outdoor unit inspection | Clear debris and maintain at least 2 ft of clearance around the unit. Look for corrosion (coastal salt exposure causes visible pitting) and straightened fins; gently brush off leaves and runoff. |

| Ductwork & insulation | Inspect for gaps and use mastic or foil-backed tape on visible seams. Insulate exposed ducts in unconditioned spaces to at least R‑6 to reduce heat loss and condensation. |

| Condensate & combustion safety | Ensure condensate drains are clear and, for gas furnaces, test carbon monoxide detectors and have a combustion safety check during your service visit. |

| Schedule professional tune-up | Book an annual HVAC inspection before December for system cleaning, refrigerant check, and performance testing by a licensed technician. |

Preparing Your System for Winter

You should begin by changing filters and completing a quick in-home test: replace the filter every 30-90 days, then set your thermostat 5°F higher than the current room temperature to confirm the heat source starts and warm air appears at vents within a few minutes. For heat pumps, switch to heat mode and watch the outdoor unit for proper defrost cycles-excessive ice that doesn’t clear during defrost indicates a service issue.

Outside, remove leaves, grass clippings, and other debris from around the condenser and keep a 2‑foot clearance to ensure airflow; coastal homes should inspect coils more frequently for salt corrosion. Inside, check exposed duct seams and apply mastic or foil tape where you see gaps, and insulate ducts in attics or crawlspaces to at least R‑6 to reduce energy loss during colder nights. Finally, if you have a gas furnace schedule a professional combustion and CO test as part of your pre-winter tune-up.

Troubleshooting Common Winter Issues

If airflow feels weak or rooms are unevenly heated, start with the basics: inspect and replace the filter, verify the thermostat is level and away from drafty windows or direct sunlight, and check the circuit breaker for tripped switches. For heat pumps, visible ice on the outdoor coil during steady operation is often normal during defrost cycles, but persistent glazing or a unit that stays iced for hours warrants a technician-especially if you also notice reduced heat output.

Short cycling (system turning on and off rapidly) often signals an airflow restriction, oversized thermostat settings, or an electrical issue; note the cycle length and call a pro if it happens more than 3-4 times per hour. If the furnace produces unusual odors, the pilot/ignition fails repeatedly, or registers stay cold despite the blower running, shut down the system and contact a licensed service provider-these can indicate ignition, heat exchanger, or refrigerant problems that require tools and training to diagnose safely.

For problems that hint at refrigerant leaks (hissing sounds, oily residue, or a sharp drop in heating performance) or safety hazards like a gas smell or carbon monoxide alarm, stop using the system and arrange emergency service; technicians use pressure gauges, leak detectors, and combustion analyzers to locate faults and prevent further damage or danger. Scheduling the inspection early in the season helps catch these issues before a cold spell turns them into an emergency.

Key Factors Influencing HVAC Performance

Your system’s age and maintenance history set the baseline for winter performance: filters changed every 1-3 months keep airflow steady, while neglected units often lose 10-20% efficiency from dust, worn bearings, and refrigerant drift. Thermostat accuracy matters too-a miscalibrated thermostat can run your system 2-4°F longer each cycle and inflate energy use. Outside factors like debris around the condenser (keep 2-3 feet clear), corrosion from coastal salt air, and blocked return grilles directly reduce capacity when you need heat the most.

The most common performance drivers are practical and measurable:

- Equipment age and rated efficiency (SEER, AFUE, HSPF)

- Filter and coil cleanliness – change or clean filters every 1-3 months

- Duct condition – leaks and poor insulation can waste 10-30% of conditioned air

- Thermostat placement and calibration

- Outdoor unit clearance and corrosion risk in coastal areas

- Proper system sizing and quality of installation (Manual J load calculations)

Recognizing which of these is causing the issue helps you prioritize fixes that deliver the biggest comfort and efficiency gains for the least cost.

Energy Efficiency Ratings

You should look at AFUE for gas furnaces, HSPF for heat pumps, and SEER for air conditioners when assessing winter performance. AFUE indicates how much fuel converts to heat-an 80% AFUE furnace wastes about 20% of the fuel, while a 95% AFUE model uses roughly 16% less gas for the same output (1 – 80/95 ≈ 0.158). Heat pumps are common in Texas; a unit with HSPF 9-11 will typically outperform older HSPF 6-7 models during mild winters, and modern units also include variable-speed compressors that maintain temperature with fewer cycles.

Efficiency numbers alone won’t save you money if the system is oversized or poorly installed. You should insist on a proper Manual J load calculation; oversizing by 20% or more can increase short-cycling, reduce dehumidification, and cut seasonal efficiency by noticeable amounts. When you compare models, factor in realistic local loads and installation quality in addition to SEER/HSPF/AFUE ratings to predict winter performance accurately.

Home Insulation and Sealing

You’ll see the biggest seasonal benefit from attic and duct improvements in Texas. Aim for attic R-values between R-30 and R-60 depending on your location and existing insulation; R-38 (roughly 12-14 inches of fiberglass) is a common upgrade target. Wall insulation in older homes is often R-13-R-15, and upgrading to R-19-R-21 where possible reduces heat loss. Ducts routed through unconditioned attics can lose 20% or more of conditioned air if they’re leaky or inadequately insulated, so you should inspect and seal them before winter.

You can use mastic or UL 181 foil-backed tape on duct joints, spray foam at rim joists, and blown-in cellulose or fiberglass to boost attic R-value. A blower door test or infrared scan will pinpoint air leaks around penetrations, recessed lights, and gaps in the envelope. Many Texas homeowners who combine attic insulation upgrades with duct sealing report energy savings in the 10-30% range depending on the starting condition.

For more targeted action, check attic insulation depth with a ruler (12-14 inches is R-38 for fiberglass), ensure baffles keep a clear channel for soffit vents, and seal gaps larger than 1/4 inch around plumbing and wiring with canned spray foam or caulk; sealing the attic-to-house interface and insulating ducts with at least R-6 in unconditioned spaces typically yields the fastest payback. Use ASA-approved mastic for duct seams rather than cloth duct tape, and prioritize sealing the plenum and joints closest to the air handler where leakage has the greatest system impact.

Pros and Cons of Professional HVAC Maintenance

| Pros | Cons |

|---|---|

| Improved efficiency – routine tune-ups commonly reduce energy use by 10-20% through cleaning and refrigerant checks. | Upfront cost – typical winter tune-ups run $100-$250, and deeper repairs can add several hundred dollars. |

| Extended equipment life – maintenance can add an estimated 3-7 years to a system by preventing wear on key components. | Scheduling delays – peak-season demand can mean waits of several days to two weeks for non-emergency visits. |

| Early fault detection – technicians spot refrigerant leaks, failing capacitors, or cracked heat exchangers before they cause breakdowns. | Variable service quality – technician experience and thoroughness can differ between companies or crews. |

| Warranty compliance – documented service keeps many manufacturer warranties valid, avoiding voided claims. | Potential upsells – some providers recommend premature component replacements or unnecessary add-ons. |

| Safety checks – combustion, carbon monoxide, and electrical inspections lower household risk in colder months. | Diagnostic and travel fees – some companies add flat diagnostic charges or call-out fees for service calls. |

| Comprehensive cleaning – coil and blower cleaning restores airflow, improving indoor air quality and heating performance. | Contractor dependence – you may rely on a single provider’s availability and pricing over time. |

| Performance testing – measured airflow, static pressure, and thermostat calibration (often ±1-2°F accuracy) ensure system balance. | Licensing gaps – smaller outfits might lack EPA certification for refrigerant handling or state licenses. |

| Record keeping – professional reports give you a maintenance history useful for resale or warranty claims. | Short, cursory visits – low-cost calls sometimes only include basic checks unless you request a full inspection. |

Advantages of Hiring Experts

You get measurable results: a certified technician will test refrigerant charge, measure airflow and static pressure, and confirm thermostat calibration, which in aggregate can trim your winter energy bills by roughly 10-20%. In practice, that means a $150 tune-up can offset part of a month’s heating cost in a moderately sized home. Technicians also perform safety inspections – checking combustion seals and CO levels – that you can’t replicate with only a filter change.

Beyond immediate fixes, professionals provide documentation and manufacturer-approved procedures that protect warranties and resale value. For example, an HVAC contractor in Galveston who found early coil corrosion prevented a $1,800 condenser replacement by scheduling a controlled repair; that kind of preventive action is what keeps systems running through frequent Texas cold fronts and coastal salt exposure.

Disadvantages to Consider

Costs add up when you factor seasonal tune-ups, travel or diagnostic fees, and occasional recommended parts replacements; a full winter visit plus minor repairs can easily reach $300-$600. You should anticipate peak-season scheduling delays – technicians in La Marque and nearby coastal areas often book out around major cold snaps, which can leave you waiting unless you schedule ahead.

Service consistency varies, so you may encounter technicians with differing levels of thoroughness or transparency. That variability sometimes leads to unnecessary upsells or short visits that only include basic checks unless you request a full inspection and an itemized report.

Mitigate those disadvantages by asking for written estimates, checking for state licensing and EPA refrigerant certification, requesting a detailed checklist of tasks performed, and comparing 2-3 local providers; flat-rate tune-ups and satisfaction guarantees are common ways reputable companies reduce the risk of overpaying or getting incomplete service.

DIY Maintenance vs. Professional Help

When to DIY

You can handle routine tasks that keep airflow and efficiency stable: replace or clean 1″ pleated filters every 30-90 days (every month if you have pets or allergies), vacuum supply registers, and clear at least 2 feet of debris around the outdoor unit to prevent restricted airflow. Check your thermostat batteries and calibration – a properly working thermostat should be within about ±2°F of ambient – and flush the condensate drain line monthly to avoid clogs and water damage.

Inspect visible duct insulation for tears and seal obvious leaks with mastic or foil tape; small gaps at registers or in accessible trunk lines are often straightforward fixes. Swap to a MERV 8-11 filter for balanced filtration without overloading older blower motors, and tighten loose electrical panels or disconnects only if you’re comfortable and the power is off – otherwise leave electrical work to a pro.

When to Call the Professionals

If you hear grinding/metallic noises, detect a burning odor, notice frequent short-cycling, see a drop in airflow greater than about 20%, or your energy bill jumps by 10% or more without a change in usage, call a licensed technician. You should also schedule professional help when dealing with refrigerant issues, gas burners, suspected heat-exchanger cracks, or electrical problems; these involve safety checks and tools homeowners don’t typically have.

Technicians perform calibrated performance tests (measuring static pressure, superheat/subcooling, and amp draw), clean coils and burners, verify correct refrigerant charge, and inspect combustion safety – actions that can boost system efficiency by roughly 5-15% and extend equipment life. Expect an annual tune-up to run about $75-$200 and common repairs from a few hundred to over $1,000 depending on parts; in coastal areas like La Marque, your contractor can also treat or replace corroded outdoor coils and recommend duct sealing or insulation upgrades that can save up to about 20% on heating and cooling losses.

Conclusion

Taking this into account, you should prioritize routine tasks to keep your system reliable during Texas winters: replace or clean air filters regularly, test your heating system before cold fronts, verify your thermostat is accurate, clear debris from the outdoor unit and inspect for coastal corrosion, and have ductwork checked for leaks or poor insulation to maintain airflow, efficiency, and indoor air quality.

While you can manage basic upkeep like filter changes, you should schedule professional maintenance so a licensed technician can perform deeper inspections, system cleaning, and performance testing to catch problems early. Alex’s Air Conditioning offers professional HVAC maintenance for homeowners in La Marque, TX – schedule your winter maintenance today for dependable comfort all season long.

FAQ

Q: What should a Texas winter HVAC maintenance checklist include?

A: Replace or clean air filters every 1-3 months, test the heating system before cold fronts, verify thermostat accuracy, clear debris and vegetation from the outdoor unit, inspect for coastal corrosion, check ductwork for leaks and inadequate insulation, test safety devices (CO and smoke detectors), and schedule a professional inspection for deeper checks such as electrical connections, heat exchanger or compressor condition, and system performance testing.

Q: How often should I change or clean air filters during mild Texas winters?

A: Check filters monthly and replace or clean them every 1-3 months depending on household factors (pets, allergies, high dust). Use pleated filters with a MERV rating appropriate for your system (typically MERV 6-8 for most homes); very high MERV filters can restrict airflow on older systems. Proper filter maintenance maintains airflow, reduces strain on the blower, and helps indoor air quality.

Q: How do preparation steps differ for heat pumps versus gas furnaces in Texas?

A: For heat pumps: ensure the outdoor coil is clear, verify defrost cycle operation, check refrigerant charge and reversing valve, and inspect electrical components. For gas furnaces: inspect burners, ignition system, venting, and the heat exchanger for cracks; perform a combustion and carbon monoxide safety check. In both cases test thermostat settings and system cycling. Homeowners can do basic inspections; combustion and refrigerant work should be done by a licensed technician.

Q: What outdoor-unit care is recommended for coastal and near-coast Texas homes?

A: Keep at least 2 feet of clearance around the unit, remove leaves and debris, rinse off accumulated salt and dirt with a gentle hose spray, inspect for rust or corrosion on fins, panels, and fasteners, and ask a technician about corrosion-resistant coatings or hardware if salt exposure is frequent. Do not cover the unit while it’s in use; consider scheduling more frequent pro checks if you’re near the coast.

Q: When should I call a licensed HVAC technician and what will professional winter maintenance include?

A: Call a technician if you notice reduced airflow, uneven heating, strange noises, higher energy bills, frequent short cycling, or any gas odor and CO alarm activation. A professional inspection includes electrical and control checks, motor and capacitor testing, cleaning coils and burners, checking refrigerant levels, inspecting the heat exchanger or compressor, sealing and insulating duct leaks, calibrating the thermostat, and running performance and safety tests. Alex’s Air Conditioning provides professional HVAC maintenance in La Marque, TX; schedule your winter maintenance today for dependable comfort all season long.