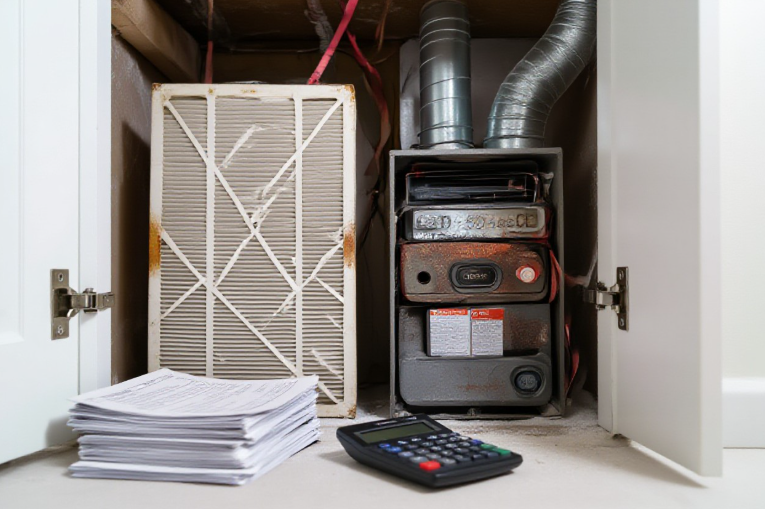

Most homeowners like you face the repair-or-replace dilemma when your HVAC falters; repairs suit newer units or minor issues, but frequent fixes on older systems often signal deeper wear and declining efficiency. Apply the 50% rule-if labor and parts near half the cost of a new system, replacement usually pays off-especially as rising energy bills and coastal Texas humidity and corrosion accelerate failures. Alex’s Air Conditioning gives honest assessments to help La Marque homeowners decide smartly.

When HVAC Repairs Make Sense

If your system is under 10-12 years old and the issue is isolated-failed capacitor, a stuck contactor, or a clogged condensate line-repairing often preserves life and restores efficiency at a fraction of replacement cost. Use the 50% rule: if the repair estimate approaches half the cost of a new system, replacement usually wins; otherwise a targeted fix that costs a few hundred dollars can be the smarter choice. You should also weigh recent maintenance history-units with regular tune-ups and clean coils are more likely to respond well to repairs than neglected systems.

Seasonal context matters in coastal Texas: humidity and salt air accelerate corrosion, so a one-off electrical or sensor repair might make sense on a 6‑year‑old unit, while repeated refrigerant leaks or coil corrosion on a 14‑year‑old system point toward replacement. Alex’s Air Conditioning assesses runtime hours, repair frequency, and utility bills for La Marque homeowners to quantify whether a repair will deliver at least a couple more years of reliable service before you commit to a new installation.

Signs Your System Can Be Fixed

Short-cycling, uneven cooling, and loud startup noises often trace to inexpensive components: a failing capacitor ($100-$300), a worn blower motor capacitor or belt ($150-$500), or a faulty thermostat ($80-$300). If diagnostics show the refrigerant charge is low due to a single serviceable leak and the compressor is healthy, you can typically repair the leak and recharge the system for $300-$700 and restore normal operation without replacing major hardware.

Intermittent operation that responds to reset or cleaning also favors repair. For example, a clogged drain or dirty coils causing icing and performance loss can be fixed during a $100-$250 service call and immediately improve efficiency. You should be cautious when technicians repeatedly find different major failures; multiple high-cost fixes in short order usually signal underlying age-related decline rather than isolated, fixable faults.

Cost-Effective Repair Options

Capacitor and contactor replacements are among the most cost-effective fixes and typically return the system to reliable service within a few hours of labor; parts plus labor often run $150-$600. Condensate pump swaps, thermostat upgrades to programmable or smart models, and blower motor bearings or belts are other low-to-mid cost repairs that improve comfort and control without a full system swap.

Preventive services deliver high ROI: a thorough coil cleaning, refrigerant leak test, and calibration during a $100-$250 tune-up can cut energy use and delay replacement. In coastal settings, paying for seasonal coil protection and anti-corrosion treatments that cost a few hundred dollars can extend coil life by years and reduce emergency callouts.

Alex’s Air Conditioning typically provides itemized repair estimates showing part, labor, and expected remaining lifespan so you can compare the repair cost to replacement quotes; use those numbers to apply the 50% rule and factor in projected energy savings from a new high‑SEER unit when deciding.

When Replacement Is the Better Option

If your system is older than about 12-15 years, has required multiple repairs in the past 12 months, or needs a single repair that approaches half the cost of a comparable new install (the “50% rule” – for example, a $2,500 repair versus a $5,000 replacement), replacement is often the smarter financial choice. You’ll also want to factor in rising energy bills: swapping a low‑efficiency unit for a modern system can cut cooling costs substantially and eliminate the cycle of emergency service calls during peak summer months in coastal Texas.

Given the salt air and humidity in La Marque, corrosion and shortened component life accelerate the decline of older units, so replacement can reduce the chance of unexpected failures and costly overnight repairs. Alex’s Air Conditioning provides local assessments that weigh repair history, current efficiency, and expected remaining life to help you decide whether replacing now delivers better long‑term value.

Indicators for HVAC Replacement

If you’re seeing two or more repairs a year, uneven temperatures between rooms, or a steady rise in monthly energy consumption (for example, a 10-20% jump without other causes), those are clear signals to consider replacement. Age is a major factor: systems older than 12-15 years typically have worn compressors and declining SEER ratings; replacing a SEER‑8 unit with a SEER‑16 or higher can reduce energy use by roughly 20-40% depending on climate and usage patterns. Visible rust on coils, refrigerant leaks, or a blown compressor are technical red flags that often justify replacement rather than ongoing repairs.

Cost comparisons matter: typical repair bills range from a few hundred to a few thousand dollars, while full replacements in your area commonly fall between $4,000 and $10,000 depending on capacity and efficiency. If a single component failure (like a compressor) would cost you more than about half the replacement price, or if the unit has less than five years of expected useful life left, you should seriously evaluate a new system – especially in seaside environments where future corrosion can drive repeated failures.

Long-Term Benefits of a New System

Upgrading delivers measurable benefits: higher efficiency lowers your monthly bills, newer compressors and variable‑speed blowers improve humidity control and comfort, and sound levels drop significantly – often by 5-10 decibels. Modern systems also integrate with smart thermostats and zoning controls to optimize runtime, which can further trim energy use and improve room‑by‑room comfort during hot, humid Texas summers.

Beyond immediate savings, new installs come with longer warranties (commonly 5-10 years on parts), better filtration options that improve indoor air quality, and features designed to resist coastal corrosion such as coated coils and sealed cabinets. Utility rebates, manufacturer incentives, and possible tax credits in 2026 can reduce your upfront cost and shorten the payback period compared with ongoing repair expenses.

To estimate payback, use a simple lifecycle calculation: if a replacement costs $6,000 and saves you $80 per month ($960 per year) while eliminating frequent $300-$1,000 service calls, your effective payback falls into the 5-8 year range depending on local energy prices and incentives – a reasonable horizon if you plan to stay in the home and value reliability during peak seasons. Alex’s Air Conditioning can run that analysis for your specific home, factoring in unit sizing, local humidity impacts, and available rebates.

Cost Considerations

Repair Costs vs. Replacement Costs

Typical repairs can range from a simple charge‑out and refrigerant top‑up at $150-$400 to major component replacements such as a compressor or condenser coil that commonly run $1,200-$3,000. You can use the “50% rule” as a practical benchmark: if a single repair approaches half the estimated cost of a new system, replacement usually delivers better long‑term value. For example, if a new central 16‑SEER system in La Marque is quoted at $7,500 installed, a $3,500 compressor swap would push you past that threshold.

Energy savings and failure risk should factor into the math: upgrading an older 10-12 SEER unit to a modern 16-20 SEER system typically cuts cooling energy use by roughly 20-40% depending on your home and usage, which can translate to $200-$600 less in annual bills. You should also account for coastal Texas corrosion and humidity that accelerate wear and raise the odds of emergency calls-after‑hours emergency repairs often add 25-50% to labor costs-so frequent fixes on a salty‑air‑worn unit often point to replacement as the smarter financial move. Alex’s Air Conditioning will run honest comparisons for La Marque homeowners to show lifecycle cost differences.

Financing Options for HVAC Systems

You have multiple financing routes: personal loans or credit cards for shorter terms, home equity loans/HELOCs for lower rates with longer terms, contractor or manufacturer financing (often promotional 0% for 6-24 months), and PACE or utility‑backed programs where available. Typical installed system costs in your area fall between $5,000 and $12,000; financing $8,000 at a 6% APR over 10 years is roughly $85-$90 per month, while a 0% promotional plan for 24 months would be about $333 per month but avoid interest if paid on time.

Rebates and incentives can materially reduce your out‑of‑pocket: local utility or state rebates in Texas often range from $200 to $1,000 for qualifying high‑efficiency equipment, and manufacturer promotions add another $200-$500 in many cases. You should check current federal and state energy incentives that may cut several hundred to a few thousand dollars from the net cost; Alex’s Air Conditioning can help identify available programs and bundle rebates into your financing package.

Get pre‑approvals and compare APR, term length, total interest, and any deferred‑interest fine print before signing; promotional financing that converts to a high APR if you miss a payment can cost you more than a modest rate on a fixed‑term loan. Ask your contractor for a payment‑breakdown scenario (monthly payment, total interest paid, and rebate application timing) so you can compare a straight repair, financed replacement, and cash purchase side‑by‑side.

Coastal Climate Impact

Salt-laden air and persistent humidity in coastal Texas accelerate wear on outdoor coils, fins, and electrical connections, so you’ll often see corrosion and pitting years earlier than in inland installations. Average summer relative humidity along the Gulf Coast regularly sits in the 70-80% range, which increases run time and creates more opportunities for moisture-related failures such as refrigerant leaks, motor and capacitor burnout, and clogged drain lines.

If your unit is older than 10 years and you’re already calling for humidity-related repairs every season, that trend eats into the “50% rule” calculus-frequent fixes and declining efficiency often push replacement into the smarter move to avoid emergency failures during peak heat. Alex’s Air Conditioning sees many La Marque homes where replacement of a corroded 12-15 year unit prevented repeated summer breakdowns and stabilized cooling costs and reliability.

How Humidity Affects System Longevity

High indoor and outdoor humidity raises the latent cooling load, so your system runs longer to strip moisture from the air; that extended runtime increases cumulative compressor hours and accelerates wear on bearings, start capacitors, and controls. You’ll notice signs like persistent condensation around the drain pan, mold or musty odors from the evaporator coil, and shorter intervals between motor or capacitor failures.

When you find visible corrosion on the outdoor coil, repeated drain-clog calls, or shrinking cooling capacity, those are practical indicators that aging plus humidity is shortening component life. For decision-making, pair those observations with repair cost estimates: if seasonal repair totals approach half the price of a new high-efficiency system and the unit is over a decade old, replacement typically offers lower total cost of ownership and fewer emergency service calls.

System Efficiency in Coastal Areas

Salt corrosion and biological fouling reduce heat-transfer efficiency, so a once-efficient condenser can lose 10-30% of capacity and efficiency over several years in a coastal setting if not protected and maintained. That drop shows up as longer run times, higher energy bills, and reduced comfort-especially on muggy afternoons when dehumidification is working hardest.

Upgrading to a modern system with coated coils, stainless fasteners, and a 16-20 SEER unit (versus typical decade-old 10-12 SEER equipment) can cut your cooling energy use roughly 15-25% and reduce runtime by using variable-speed compressors and better controls. Regular coil cleanings, annual corrosion inspections, and investing in factory-applied salt-resistant coatings can slow efficiency loss and extend service life.

When weighing repair versus replacement in a coastal home, factor in projected energy savings, expected remaining life given corrosion exposure, and local replacement costs; for example, if a quoted repair is $3,000 and a properly sized, high-efficiency replacement is $8,000, repair is below the 50% threshold but the coastal exposure and frequency of past repairs may still make replacement the smarter long-term choice-Alex’s Air Conditioning can run that cost-of-ownership comparison for your La Marque home.

Environmental Impact

When you weigh repair versus replacement, factor in both operational energy use and lifecycle emissions: older systems run longer and less efficiently, so they burn more electricity and drive higher CO2 output from your utility mix. An older 8-10 SEER unit can consume roughly 30-50% more energy than a modern 16-18 SEER system, so repeatedly repairing an inefficient unit prolongs a higher-emissions footprint and keeps your bills elevated. Using the “50% rule” for cost makes sense financially and, often, environmentally – replacing a worn system can cut annual energy consumption substantially.

Coastal humidity and corrosion accelerate wear and force compressors and fans to work harder, which amplifies those environmental costs in places like La Marque. When Alex’s Air Conditioning swapped a 2006-era 8 SEER condensing unit for a 16 SEER inverter heat pump in a La Marque home, the homeowner’s cooling energy fell about 35% and corrosion-resistant coatings extended the expected service life, lowering total lifecycle impact while avoiding emergency replacements during peak summer months.

Energy Efficiency Standards

You should check SEER (Seasonal Energy Efficiency Ratio) and HSPF (Heating Seasonal Performance Factor) ratings when comparing options; newer test procedures (SEER2/HSPF2 implemented by DOE in recent years) mean labeled numbers can differ from older ratings, so compare like for like. Modern high-efficiency central systems usually advertise SEER in the 16-26 range, while cold-climate heat pumps list HSPF and COP values that show strong heating performance – a properly sized, variable-speed heat pump can deliver 300-400% effective heating (COP 3-4) under moderate conditions.

Minimum federal and regional standards have tightened, and ENERGY STAR or utility-qualified models exceed those baselines – that gap is where you find the greatest long-term savings. Incentives matter: many state and utility rebates and federal programs target high-efficiency heat pumps and ENERGY STAR equipment, with typical incentives ranging from a few hundred to several thousand dollars, so factor those into your replacement math alongside projected energy savings.

Eco-Friendly HVAC Options

Switching to an air-source heat pump, geothermal system, or solar-assisted HVAC unit is one of the most effective ways you can lower both energy use and greenhouse gas emissions from home heating and cooling. Air-source heat pumps with inverter-driven compressors and variable-speed fans now routinely reach SEER 18-22 and HSPF values that make them competitive with gas furnaces for annual cost and emissions in many climates, while ground-source (geothermal) systems offer even higher COPs year-round – often 3.5-5 – though with higher upfront installation costs.

Low-global-warming-potential (GWP) refrigerants are becoming standard: newer blends such as R-454B cut GWP by roughly 70-80% compared with older R-410A formulations, meaning that when you replace a system you also reduce the climate impact of any future refrigerant leakage. You can also ask for corrosion-resistant coils, coated condensers, and sealed ductwork to improve longevity and efficiency – small upgrades that reduce energy waste and the need for premature replacement, particularly in humid coastal environments.

Proper disposal and refrigerant reclamation further matters: when you replace equipment, ensure your contractor recovers and recycles refrigerant and metals, and that the new system is charged to manufacturer specs to minimize leakage. You’ll get the best environmental outcome when high-efficiency equipment, low-GWP refrigerants, and good installation practices are combined – that’s the package Alex’s Air Conditioning recommends to La Marque homeowners seeking both lower bills and lower carbon impact.

Maintenance Tips for Longevity

Prioritize routine care to keep repair needs low and efficiency high; systems that receive regular attention often avoid the frequent breakdowns that push owners toward the “50% rule” replacement decision. In coastal Texas, add corrosion checks to your checklist since humidity and salt can accelerate wear and cut useful life by years if left unchecked.

- Change disposable filters every 1-3 months; a clean filter can improve system efficiency by up to 10-15% and reduce strain on the blower motor.

- Schedule a professional tune-up annually (typical cost $80-$200) to inspect refrigerant levels, tighten electrical connections, and clean coils-preventive service often costs far less than a single $500+ emergency repair.

- Keep outdoor unit clear of debris and vegetation; maintain 2-3 feet of clearance and rinse coils annually to prevent salt and pollen buildup.

- Inspect ductwork every 3-5 years for leaks and gaps; sealing ducts can recover 10-30% of lost airflow and improve comfort without oversized equipment.

- Monitor thermostat runtime and utility bills monthly; a persistent 10%+ year-over-year rise in HVAC-related energy use signals maintenance or replacement needs.

Regular Maintenance Practices

If you handle basic tasks yourself, start with filter changes and keeping vents unobstructed-these simple steps reduce wear on fans and compressors. During a professional visit insist on refrigerant-charge verification (correct charge prevents compressor stress), motor lubrication where applicable, and condensate drain cleaning to avoid water damage and microbial growth.

When you schedule service, ask the tech to measure static pressure and airflow; low airflow readings often point to duct or coil issues that a simple filter change won’t fix. In coastal areas like La Marque request corrosion inspection and protective coating recommendations for the outdoor coil and fasteners, since salt-air corrosion can accelerate failures and lead to emergency replacements.

Signs That Maintenance Is Needed

If your system shows decreased airflow, uneven room temperatures, or frequent short-cycling, you should act quickly-those symptoms often precede major component failure. Rising energy bills by 10% or more without a corresponding change in usage, visible rust on the outdoor unit, ice on the evaporator coil, or persistent odors are all clear indicators that maintenance or repair is overdue.

Pay attention to noise and runtime patterns: a compressor that runs constantly, or interior blower noise above about 60 dB, suggests inefficiency or impending mechanical failure. Also track repair frequency and costs-if you pay more than $500 in repairs in a single season or if one repair approaches half the price of a replacement system, weigh replacement options.

Use basic monitoring to catch problems early: compare monthly kWh for the HVAC portion of your bill year-over-year, log thermostat run-times, and perform a visual check of the outdoor unit monthly during humid months; Alex’s Air Conditioning has reduced emergency calls by about 40% for La Marque customers who follow this simple monitoring plus annual service regimen.

Assume that scheduling an annual professional tune-up and changing filters every 1-3 months will significantly lower your emergency repair risk and commonly extend system life by 2-5 years.

Conclusion

With these considerations, you should favor repair when your HVAC is relatively new and the issue is minor, but opt for replacement when repairs are frequent, the unit is old, or repair estimates approach the “50% rule” of a new system’s cost. Pay attention to rising energy bills and declining efficiency, as those are clear indicators that ongoing fixes may cost you more in the long run.

In coastal Texas, your system endures extra humidity and corrosion that accelerate wear and increase the chance of emergency failures, so replacement often delivers better efficiency, quieter operation, and more reliable comfort during peak seasons. Have Alex’s Air Conditioning perform an honest assessment so you can weigh system age, repair history, energy costs, and coastal exposure to make the decision that best protects your comfort and budget.

FAQ

Q: How should I decide whether to repair or replace my HVAC system in 2026?

A: Check the unit’s age, frequency of breakdowns, recent repair history and energy bills. Newer systems with isolated issues often make sense to repair; older units that need repeated fixes or show declining efficiency are better candidates for replacement. Use the “50% rule” (see next question) as a guideline, factor in expected remaining lifespan, and get an honest assessment from Alex’s Air Conditioning to quantify costs and benefits for La Marque homes.

Q: What is the “50% rule” and how do I apply it this year?

A: The 50% rule compares the repair cost to the price of a new system (including installation). If a repair approaches or exceeds half the cost of replacement, replacing is usually the smarter financial choice. Also weigh remaining service life, warranty coverage, and potential energy savings from a new, higher-efficiency unit before deciding.

Q: How do rising energy bills and efficiency ratings affect the repair vs. replace choice?

A: Newer HVAC systems have higher SEER ratings and lower operating costs. If a replacement will deliver significant annual energy savings, those savings can shorten the payback period and justify upfront cost. Estimate yearly savings from a more efficient unit and compare that to repair expenses and expected remaining life of the existing system.

Q: Does living in coastal Texas change the decision to repair or replace?

A: Yes. Coastal humidity and salt air accelerate corrosion and wear on compressors, coils and electrical components, shortening system life and increasing the risk of sudden failure. In La Marque and similar areas, replacement is often recommended earlier than inland locations to avoid costly emergency breakdowns and to gain the reliability of newer materials and coatings designed for coastal conditions.

Q: What are the main benefits of replacing now, and when should I schedule installation?

A: Replacement brings better efficiency, quieter operation, improved comfort, modern controls, factory warranties and fewer unexpected outages. It also reduces the likelihood of emergency service during peak seasons. Schedule installation during off-peak months if possible for better availability and pricing. Contact Alex’s Air Conditioning for a tailored assessment, including potential rebates or financing that may lower your net cost.