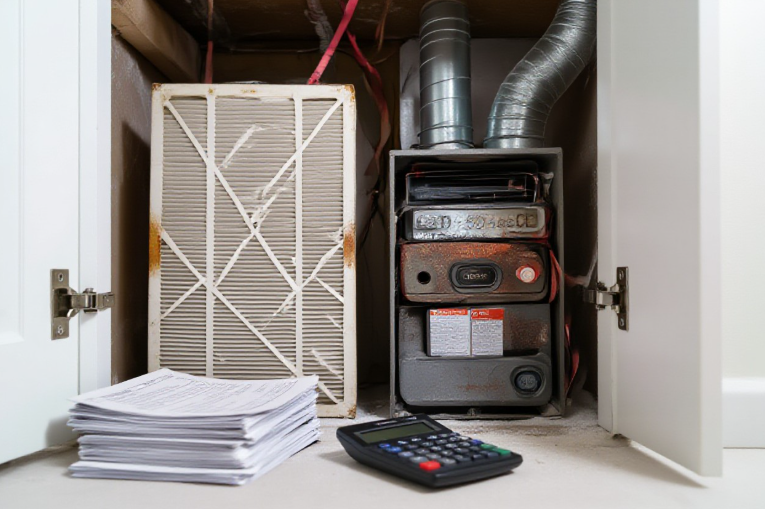

Costs tied to an inefficient HVAC often show up as higher energy bills and uneven temperatures, signs you may be paying more to maintain comfort. Frequent repairs, strange noises or odors, and accelerated wear-especially in older units exposed to coastal moisture-signal hidden inefficiencies and failing components. A professional inspection can pinpoint problems before an expensive breakdown; Alex’s Air Conditioning helps La Marque homeowners restore system efficiency and reduce operating costs.

Common Warning Signs

If your system is costing more than it should, several specific signs will show up in day‑to‑day use: uneven temperatures of 5-10°F between rooms, frequent short cycling, and a steady climb in repairs or replacement parts. You should treat repeated component swaps-capacitors, motors, or compressor start kits-as a symptom of systemic decline rather than a series of isolated fixes; replacing parts repeatedly often means the system is operating 10-30% less efficiently than when new, especially if the unit is over 10 years old.

Coastal homes demand extra attention because salt air accelerates corrosion on coils, fan blades, and electrical connections, which translates directly into lower heat‑transfer efficiency and higher run times. You’ll save most by acting early: a professional inspection can pinpoint airflow restrictions, refrigerant loss, or degraded coils before those issues push bills and repair costs substantially higher.

Unusual Noises

If you hear grinding, banging, or a high‑pitched squeal, you’re hearing mechanical distress. Grinding commonly indicates failing motor bearings, while loud banging or clunking can signal a failing compressor or loose components that may cause catastrophic damage if left running; hissing often points to a refrigerant leak. You should shut off the system and schedule a technician immediately for any metal‑on‑metal or explosive noises, because compressor failure alone can cost $1,500-$3,500 to replace depending on unit size.

Less severe sounds still matter: irregular rattles often come from loose panels or ductwork, and persistent squeals can be a worn belt or failing fan motor that will draw extra amperage and increase your energy use. In La Marque’s salty air, slight corrosion can turn a minor vibration into a major failure quickly, so you should treat a new or worsening noise as the start of a diagnosis rather than a nuisance.

Increased Energy Bills

Compare your bills month‑to‑month and year‑over‑year; a 10% or greater jump in cooling costs without changes in thermostat settings or occupancy is a red flag. For context, upgrading from a 10 SEER to a 16 SEER air conditioner reduces cooling energy use by about 37.5% (10/16 = 0.625), so aging or low‑SEER equipment can be the main driver of rising bills. You’ll also notice longer run times and more frequent cycling when efficiency drops.

A practical example: one La Marque homeowner Alex’s Air Conditioning inspected was paying roughly 25% more in summer electric bills because the outdoor condenser coil was fouled and corroded, reducing heat transfer and forcing the system to run 30-40% longer each day. After coil cleaning and replacing a corroded fan motor, runtime dropped and monthly bills returned to expected levels.

Start your own troubleshooting by checking simple culprits first: dirty air filters can increase system energy use by 5-15%, and leaky ducts can lose 20-30% of conditioned air-both directly inflate bills. You should also verify thermostat programming, measure runtime during peak hours, and schedule a professional tune‑up; a technician will test refrigerant charge, inspect coils, and calculate system efficiency so you can weigh repair versus replacement based on measured savings.

Why These Issues Increase Costs

Inefficiency and Energy Waste

Your HVAC can quietly burn through 40-50% of your home’s energy budget when it’s not operating efficiently, so small losses add up fast. Leaky ducts commonly dump 20-30% of conditioned air into attics or crawl spaces, forcing the system to run longer; a clogged filter can increase energy use by roughly 5-15%, and refrigerant charge issues or a failing coil can push efficiency down another 10-20%. When each cycle takes longer to reach setpoint, your meter reflects every extra minute.

Uneven temperatures and short-cycling aren’t just comfort problems – they indicate increased run time and higher bills. In coastal La Marque, for example, elevated humidity raises the latent load, often increasing run time by 10-25% compared with drier inland locations, so a degraded system there will cost noticeably more to maintain the same comfort level. Targeted fixes like sealing ducts, replacing filters quarterly, and correcting refrigerant levels frequently cut energy use enough to pay for themselves within a season or two.

Potential Repair Needs

Frequent part replacements signal a system in decline and a steady drain on your wallet. Common repair costs vary widely: a capacitor or contactor replacement typically runs $100-$300, a blower motor $300-$700, while compressor or condenser replacements can hit $1,200-$3,000 or more. If you’re replacing major components every year or two, those cumulative costs often exceed the value of the aging equipment and justify a full system replacement.

Corrosion and moisture-related damage in coastal homes accelerate component failures, increasing both frequency and severity of repairs. Technicians often find evaporator and condenser coils pitted by salt air, which reduces heat transfer and forces the compressor to work harder; replacing corroded coils or the compressor can turn a $200 seasonal fix into a $2,000 emergency bill. As a practical rule, if annual repair bills approach 50% of the cost to install a new, high-efficiency system-or if you face repeated compressor or coil failures-you should seriously weigh replacement.

Alex’s Air Conditioning technicians in La Marque routinely document cases where routine maintenance caught refrigerant leaks or failing capacitors before they escalated into compressor failure, saving homeowners thousands; conversely, delaying action in that same climate frequently shortens system life by 3-5 years and multiplies long‑term costs. Scheduling inspections that include electrical checks, coil condition assessment, and a duct leakage test gives you the data to decide whether continued repairs or a replacement will be the smarter financial move.

Coastal Texas Risk Factors

Your system faces two compounding threats on the coast: persistent humidity and salt-laden air. Humidity levels in Gulf Coast summers regularly sit between 60% and 90%, forcing your AC to run longer to shed latent heat and increasing runtime by roughly 20-40% compared with drier months. At the same time, salt accelerates metal oxidation and electrical contact corrosion, which can turn what would be a minor repair into a major service call within a few seasons. You may notice corroded condenser fins, pitted coils, or sticky contactors long before a failure shows up on your energy bill.

- High summer humidity (60-90%) increasing run time and energy use

- Salt spray and airborne chlorides accelerating coil and fastener corrosion

- Frequent condensate problems and microbial growth on drain pans and coils

- Electrical component degradation: relays, contactors, and control boards

- Reduced heat-transfer efficiency from fouled or corroded coils (up to ~30% loss)

- Shortened equipment lifespan – coastal units often age several years faster than inland units

Recognizing these patterns early lets you target the specific interventions that cut costs – more frequent coil cleanings, corrosion-resistant hardware, and prioritized inspections to catch refrigerant leaks or failing compressors before they inflate your bills.

Humidity and Corrosion

Excessive indoor moisture forces your evaporator to work harder to remove latent heat; when outdoor dew points are above 70°F, your system not only runs longer but cycles less efficiently, raising electricity consumption. Condensate that sits in pans or clogged drain lines becomes a breeding ground for mold and biofilm, which foul coils and reduce heat transfer – a dirty coil can cost you up to 10-30% in efficiency depending on buildup.

Corrosion from persistent moisture attacks copper tubing and aluminum fins, creating pinholes and reducing refrigerant containment. In La Marque, technicians from Alex’s Air Conditioning routinely find evaporator and condenser coil pitting on units older than eight years, and once pitting starts you’re looking at higher repair bills or early replacement rather than simple tune-ups.

Salt Air Effects

Salt-laden air speeds galvanic corrosion across exposed metals and degrades painted surfaces, seals, and electrical connections. Outdoor units within a mile of the Gulf commonly show visible rust on housings and mounting hardware in as little as 2-4 years, and corrosion can increase component failure rates several times over inland installations. Corroded fins and coil headers lower heat exchange efficiency and raise compressor workload.

More aggressive maintenance pays off: you should schedule outdoor-unit rinses every 1-3 months during high-salt periods, switch to stainless or coated fasteners, and consider factory-applied coil coatings or aftermarket protective sprays. Preventive steps like these – coil coating (roughly $150-$300) and biannual professional inspections – often cost far less than premature compressor or coil replacements, which can run $800-$2,500 depending on the unit and refrigerant type.

Importance of Professional Inspection

A professional inspection uncovers the invisible problems that drive up your bills: improper refrigerant charge, low airflow, electrical resistance, and corroded components in coastal homes. Technicians use diagnostics-measuring air balance (roughly 350-450 CFM per ton), temperature split across the evaporator (typically 16-22°F), amperage draw on motors, and refrigerant superheat/subcooling-to compare actual performance to manufacturer specifications and identify deviations that can cost you 5-20% or more in efficiency.

When you have a trained technician perform these checks, small fixes often replace expensive replacements: a $20-$40 capacitor or a clogged condensate line can be repaired in under an hour, whereas ignoring symptoms can lead to compressor failure running $700-$1,500 to replace. Alex’s Air Conditioning routinely finds issues in La Marque homes-stuck dampers, refrigerant leaks, corroded condenser coils-that, when corrected, cut energy use and prevent emergency calls during heat waves.

Comprehensive Evaluations

Comprehensive evaluations combine visual inspection with performance testing. Your technician should inspect coils for dirt and salt buildup, verify refrigerant pressures, test blower motor amps, measure static pressure in the duct system, and perform a leak check. Duct leakage of 15-30% is common and can cause uneven temperatures and up to a 20% rise in energy consumption; sealing and insulating ducts often yields immediate improvements.

Case studies show the value: in one La Marque home a disconnected return plenum and a 12% refrigerant undercharge produced uneven rooms and a 18% increase in monthly bills-after sealing and a proper charge, comfort normalized and energy use dropped. Your inspection report should prioritize corrective actions, list expected savings, and include before-and-after measurements so you can see the payback for each repair or upgrade.

Preventive Maintenance Benefits

Routine preventive maintenance reduces emergency repairs and improves efficiency-expect typical energy savings of 5-15% and equipment life extensions of 3-5 years when filters, coils, capacitors, and belts are serviced on schedule. During a visit, your technician will clean coils, change filters, tighten electrical connections, lubricate bearings, and verify control settings so the system runs closer to its rated SEER and avoids stress that accelerates wear.

Preventive work also targets location-specific risks: in coastal areas like La Marque, technicians watch for salt corrosion on fins and electrical terminals and apply protective measures or replace sacrificial components before failure. One routine service caught early bearing wear on a condenser fan and saved the homeowner an estimated $900 by avoiding a compressor seizure during peak summer demand.

For consistent results, schedule maintenance at least twice a year-spring for cooling, fall for heating-and ask your provider for a written checklist and measured performance metrics (temperature split, CFM estimate, amp draws) so you can track improvements and quantify the value of each service.

Call to Action

Schedule a Professional Inspection

If your energy bills are 15-25% higher than last year or you’ve had three or more repairs in two years, schedule a diagnostic now; a full inspection checks refrigerant charge, airflow, electrical connections, condensate drain, and coil condition, and can reveal issues that increase consumption by 10-20%. You’ll get a written report with prioritized repairs or replacement options-acting can extend equipment life by 3-5 years in many cases, especially in La Marque’s salt-air environment where corrosion speeds deterioration.

When you contact Alex’s Air Conditioning, request a 30-60 minute coastal-home diagnostic so the technician arrives prepared with common replacement parts and energy-saving recommendations; many homeowners see 10-30% lower bills after targeted repairs or timely replacement. If uneven temperatures, strange odors, or frequent cycling are already happening, book the inspection within 24-48 hours to avoid a costly mid-summer breakdown and get a clear cost-benefit comparison for repair versus replacement.

Final Words

Conclusively, if you notice rising energy bills, uneven temperatures, frequent repairs, or persistent noises and odors, your HVAC system is costing you more than it should. These signs – especially on older units in coastal La Marque where moisture and corrosion accelerate wear – indicate lost efficiency and hidden problems that a professional inspection can uncover before a costly failure occurs.

You should act early to evaluate repair versus replacement, restore comfort, and reduce operating costs. Alex’s Air Conditioning helps La Marque homeowners diagnose issues, improve system efficiency, and recommend the most cost-effective solution for your home.

FAQ

Q: Why are my energy bills rising even though my thermostat setting hasn’t changed?

A: Increasing bills often mean your system is losing efficiency. Dirty coils, clogged filters, low refrigerant, failing compressors or motors, and worn ductwork force the unit to run longer and draw more power to maintain the same temperature. Compare usage month-to-month and check for seasonal factors, then schedule a professional efficiency check. Alex’s Air Conditioning in La Marque can diagnose the cause, perform tune-ups, and recommend whether repairs or replacement will lower long-term costs.

Q: What do uneven temperatures or hot and cold spots in my home indicate?

A: Uneven comfort typically points to airflow problems, duct leaks or blockages, poor insulation, an improperly sized system, or malfunctioning zoning/thermostat controls. Duct sealing, rebalancing registers, and repairing failing components often restore even temperatures and reduce runtime. A diagnostic inspection by Alex’s Air Conditioning will pinpoint the issue and estimate the cost versus the expected energy savings.

Q: How many repairs are too many before I should replace the system?

A: Frequent breakdowns and repeated part replacements are a sign the system is nearing the end of its useful life; repair costs can quickly exceed the value of continued operation. Use a simple payback check: compare annual repair and operating costs against the estimated cost and efficiency gains of a new unit. Systems older than 10-15 years, especially those in coastal areas, often reach the tipping point where replacement saves money over time. Alex’s Air Conditioning can provide a cost-comparison and replacement options for La Marque homeowners.

Q: My HVAC is making odd noises and smells. When is that an emergency and when can it wait?

A: Squealing, grinding, loud banging, or persistent hissing suggest mechanical failure and should be inspected promptly. Musty or moldy odors indicate moisture and possible microbial growth in the system; burning smells or the scent of natural gas require immediate shutdown and emergency service. Routine unusual odors or noises still warrant same-day diagnostics to prevent bigger, costlier failures. Alex’s Air Conditioning offers emergency response and detailed cleaning or repair plans.

Q: Does living in a coastal climate affect how much my HVAC costs to operate and repair?

A: Yes. Salt air, high humidity, and rapid corrosion accelerate wear on coils, motors, fasteners and electrical connections, lowering efficiency and shortening component life. That increases energy use and raises repair frequency. Preventive measures-more frequent inspections, corrosion-resistant parts, protective coatings, and proactive coil cleaning-reduce long-term expense. Alex’s Air Conditioning provides coastal-specific maintenance and corrosion-mitigation services tailored to La Marque homes.